How do our adiabatic cooling solutions work?

The Adiabatic cooler is a heat exchanger. Calories are released dry to the atmosphere. As soon as the climatic conditions get warmer, this exchanger uses the evaporation of water. So, safely and without water treatment, it dissipates the calories by maintaining a cold-water temperature lower than that of ambient air.

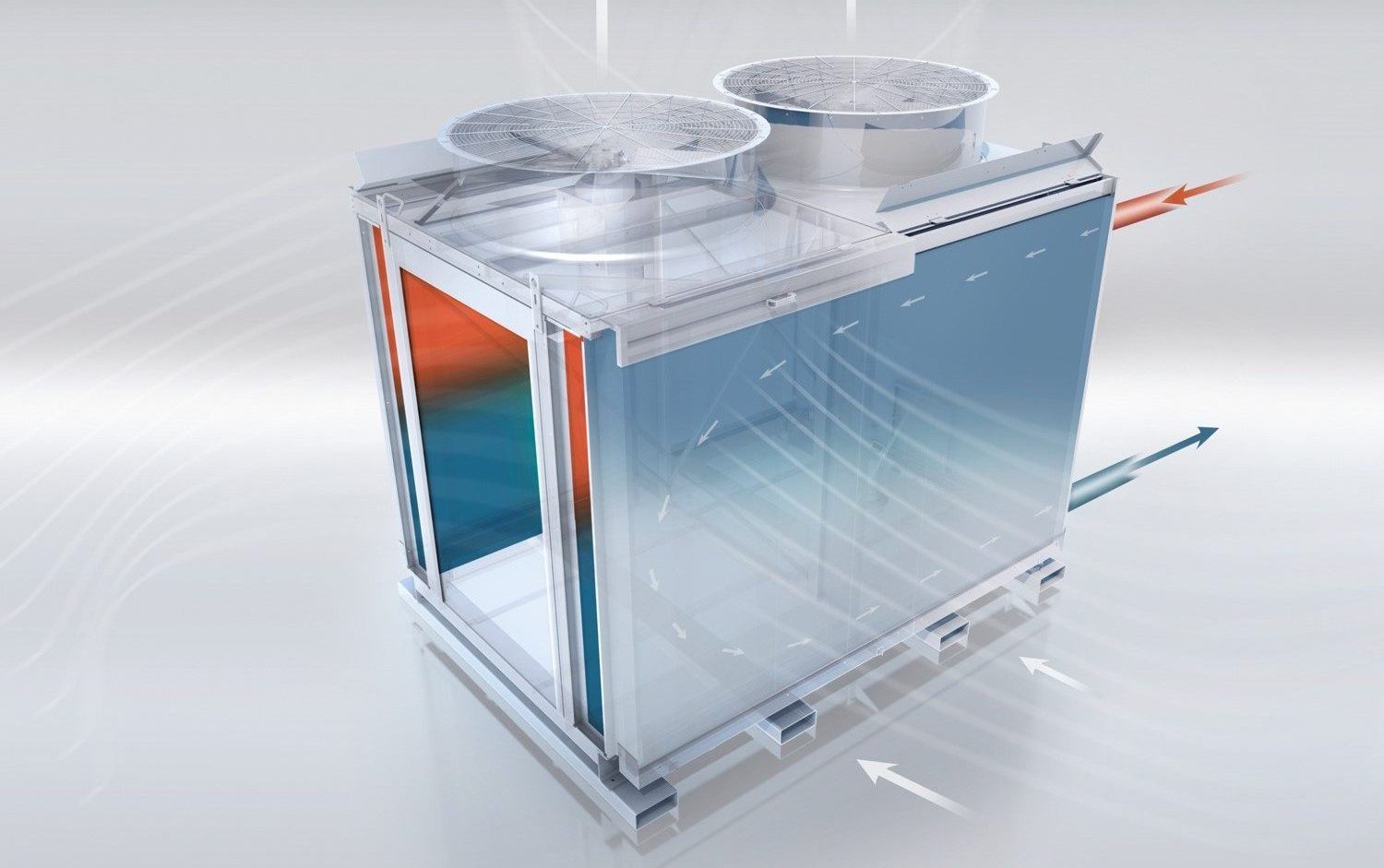

This adiabatic cooler results from the combination of a dry air cooler and an adiabatic pre-cooling section: this pre-cooling section lowers the ambient air temperature by evaporating water on humidifying pads designed specifically for this purpose.

What are the operating modes of adiabatic cooling towers?

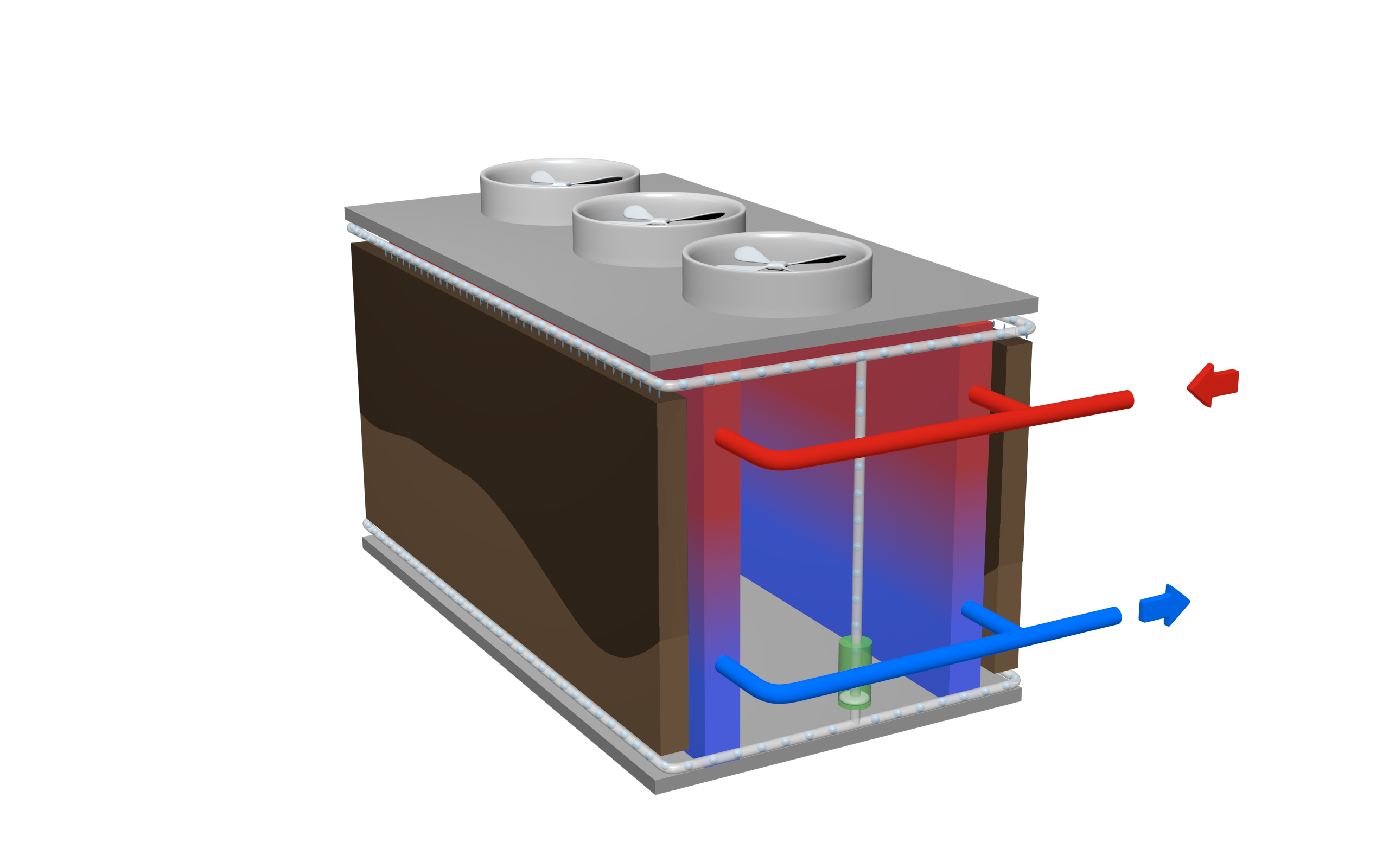

- Initially, in dry mode, the liquid is first cooled in the dry battery which is passed through by the ambient air. This air is drawn in by the fan units, while the media is dry at the inlet. The ventilation, on the other hand, is regulated according to the thermal load in order to keep the liquid outlet temperature constant.

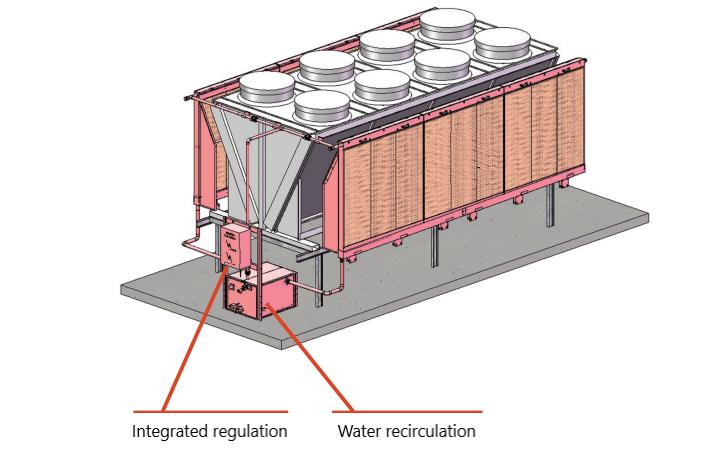

- Then, and when the dry mode is no longer sufficient, the media are moistened, in adiabatic mode. The ambient air passing through the media is cooled by humidification and is thus pre-cooled to pass through the batteries to cool the liquid. Excess humidification liquid is collected and then recycled to supplement the fluid supply.

What are the advantages and characteristics of adiabatic cooling solutions?

Our adiabatic cooling solutions are quality technologies, compliant with the NF E 38-424 standard of December 2020 and which have the following advantages and characteristics:

- Ecoconception ErP 202x compliant,

- Water consumption: 90 % savings compared with standard cooling towers,

- No Legionella risk: no water spray in air flow, independently verified, JACIR certificated,

- No water treatment require,

- Easy maintenance design,

- Even lower water consumption with recycling pump,

- Cooling and condensing at lower temperature than dry bulb temperature.

Adiabatic cooler

Adiabatic condenser