Performance of permanent magnet motors: securing the installation, reducing electrical consumption & maintenance costs.

Report

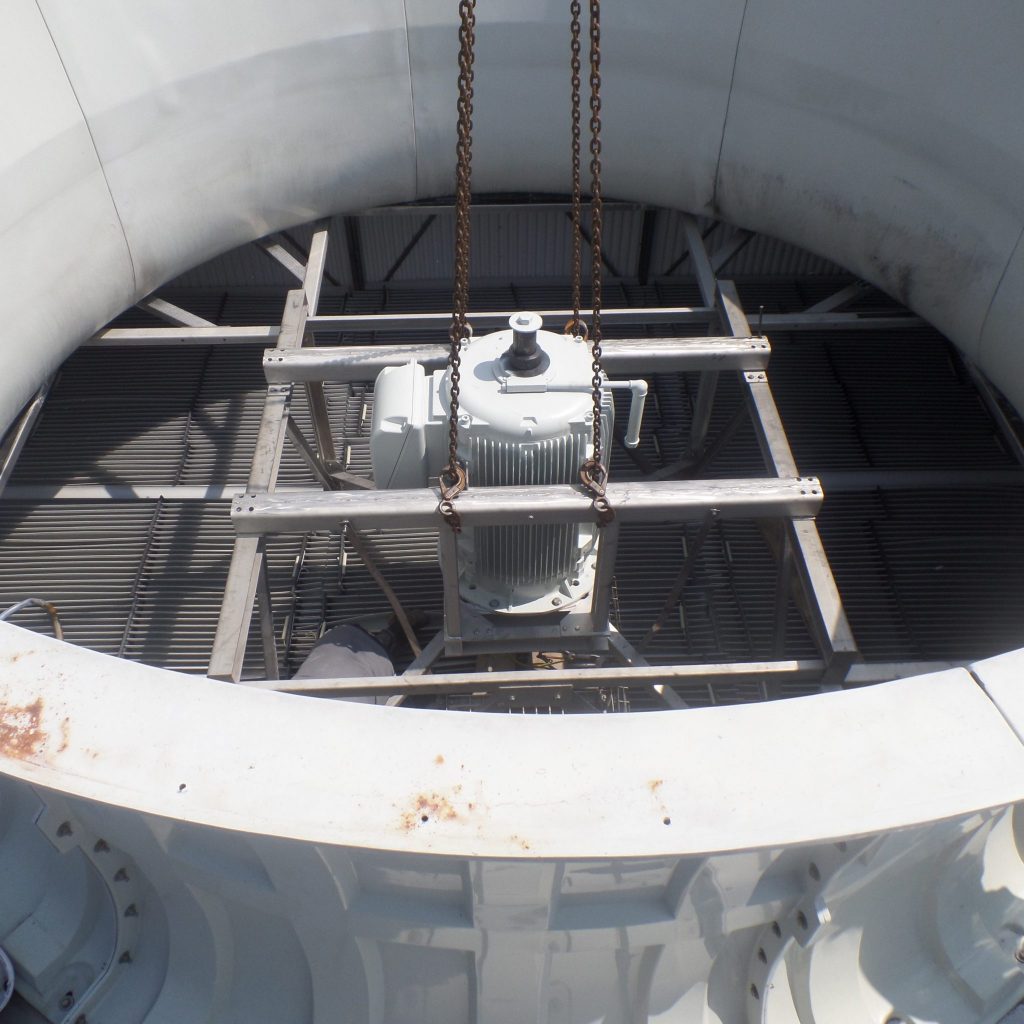

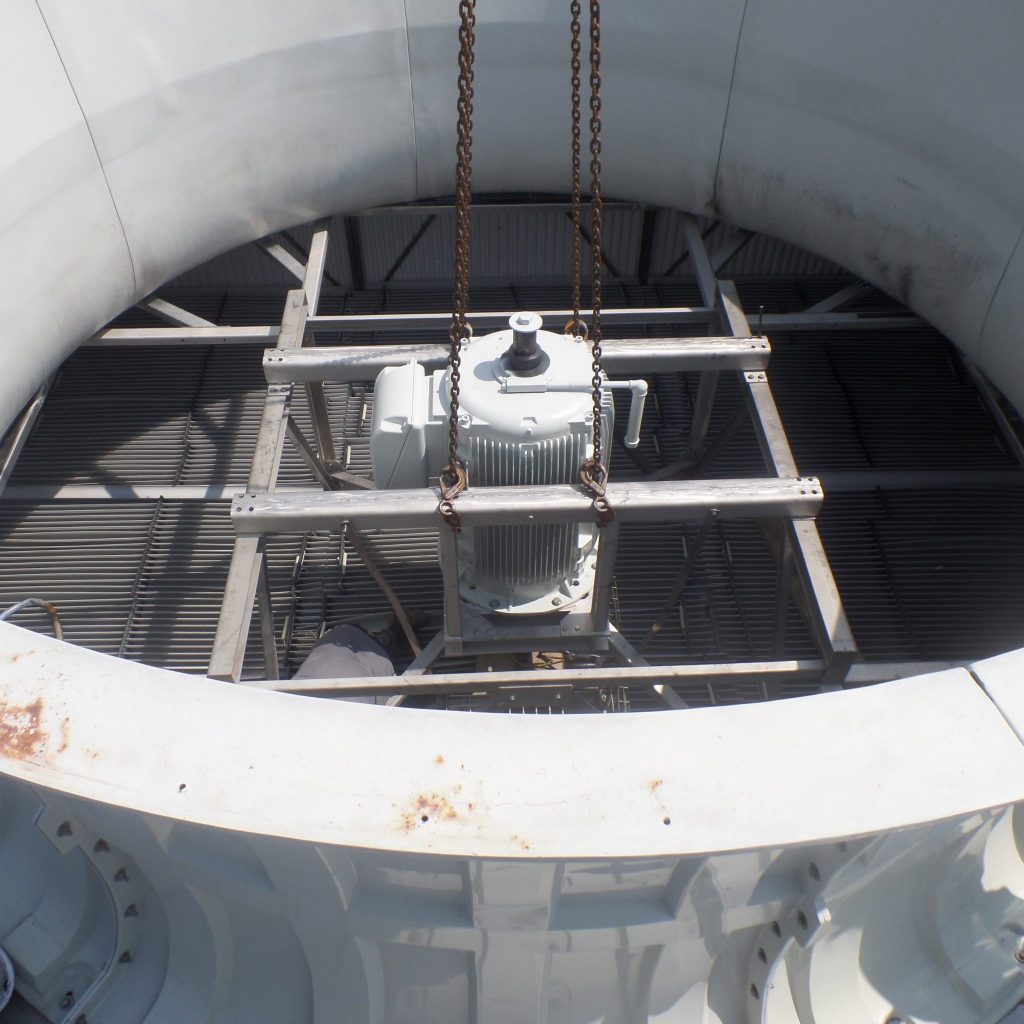

The transmission components from the motors to the fan (belts and reducer) require increased vigilance for the proper cooling of a process, in particular if they are placed in the flow of humid air. Thus, the elimination of these critical components eliminates maintenance costs and operations while securing the reliability of the equipment.

Solution

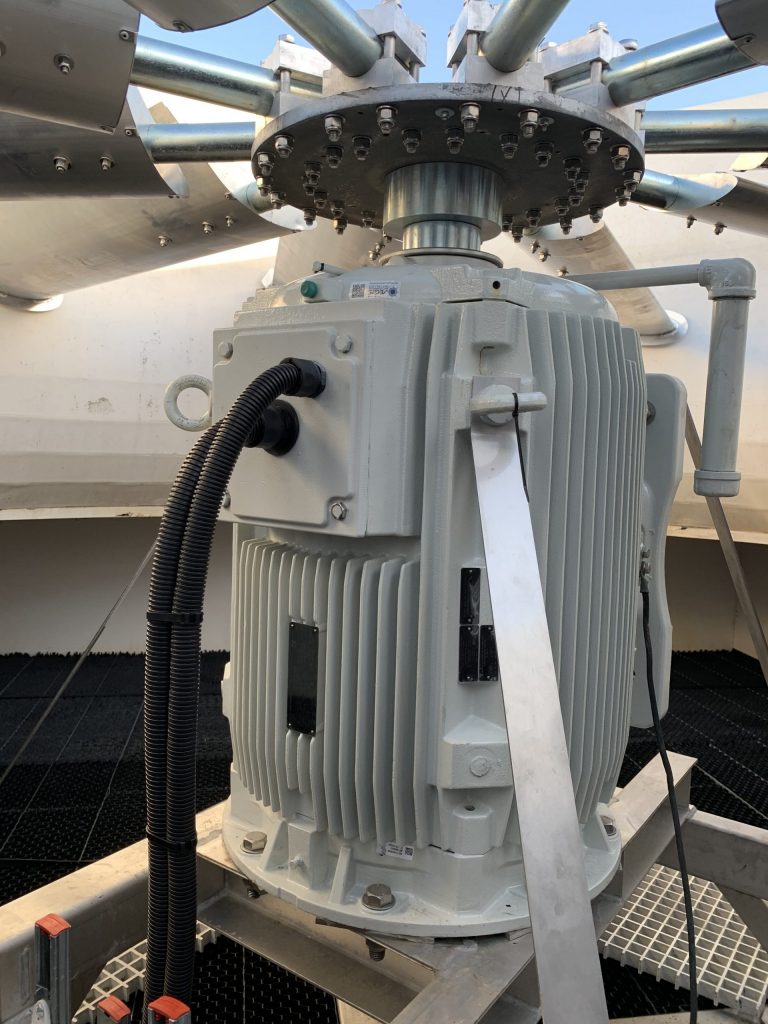

Replacing gearboxes or belts with a permanent magnet motor significantly reduces maintenance costs and handling operations.

In addition, this new generation of motors coupled to their frequency converters guarantees yields much higher than those of asynchronous motors (+ 3% minimum).

A solution that secures the installation, reduces maintenance costs: 2-year warranty.

- Better energy performance

- Suppression of reducers and maintenance (excluding bearings)

- Eligible for CEE State bonuses

The elimination of these critical components eliminates maintenance costs and operations while securing the reliability of the equipment.

In addition, this new generation of motors coupled to their frequency converters guarantees yields much higher than those of asynchronous motors.

“This motor technology, which is directly coupled to the propeller (i.e. without a gearbox), met all our requirements in every respect: less energy-consuming motors and much more precise airflow control.

Gérard DANDEVILLE, Maintenance Manager, Operational Unit CDGL

It was the deal solution to our mechanical problems and tour our recurring control and maintenance operations.”

PLUME SUPPRESSION FROM COOLING TOWERS

Plume: it is the result of the condensation of the water vapour contained in the saturated air at the outlet of the tower. It can end up in over-saturation when it mixes with the colder ambient air. The plume is therefore generally more visible in colder or more humid ambient conditions.

Plume suppression is achieved by installing a coil at the unit’s discharge. This enables to:

- Heat the moisture-saturated discharge air,

- Move it away from its saturation point,

- Avoid condensation of the vapour on its return to the atmosphere.

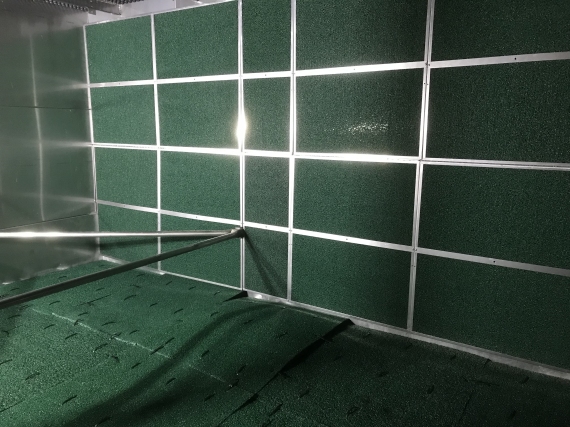

COOLING TOWER SOUNDPROOFING

Replacement or adaptation of soundproofing boxes on helical or centrifugal towers.

It is possible to lower the sound level of a cooling tower already installed on site by using sound boxes at the top of the tower for exhaust ventilation.

In the case of a blower fan (on the side) Jacir carries out the dressing of the fan motor unit.

Sound attenuation EFFI-SILENT, specially designed for cooling tower basins, reduces sound emission from 3 to 4dBA depending on the type of tower.