Technical Expertise Contract for Cooling Towers

JACIR provides you with the technical skills of its Renovation and Environment department and offers you up to two annual expertises of your cooling towers in order to achieve the following objectives:

- Securing the thermal performance of a TAR

- Prevent the Legionella risk thanks to innovative technologies “Made in JACIR”

- Prevent the risk of wear and breakage of cooling tower parts

- Reduce the time of production stoppages in the event of a breakdown with reliable equipment

- Increase the longevity of your equipment

- Contribute to the maintenance of a better environment

- Adapt towers to new regulations

- Reduce the overall cost of maintenance

We offer you this technical expertise for an annual lump sum which will be determined according to the number of passages, the number of towers and their geographical location.

Advice, expertise and know-how

Cooling towers

Cooling towers must be maintained at least once a year, both in tertiary and industrial environment, in order to prevent the development of bacteria in strict compliance with standards and regulations.

Our experience in the field as a manufacturer of cooling towers guarantees firstly an intervention by our experts trained in Legionella risks, but also personalised support for preventive maintenance, with turnkey management of the chanter.

Our experts will recommend possible technical improvements to ensure the availability, reliability and durability of your equipment.

Disinfection

Mechanical cleaning

Chemical descaling

Removal of internals

- Mechanical maintenance of fan units

- Electrical checks and measurements

- Vibration checks

- Energy optimisation – performance

Advice, expertise and know-how

Adiabatic coolers and condensers

The operating conditions and the environment of the installation are decisive in the choice of the frequency of intervention. In order to maintain the original performance, we recommand at least annual preventive maintenance.

Our experience as a manufacturer of adiabatic equipment has shown over the years that the maintenance contract set up with our customers has largely contributed to the durability of the machines and their components.

Humidifying pad

- Control

- Cleaning

- Replacement

Silenced cylinders at discharge

- Performance improvement: soundproofing

Coils

- Control

- Cleaning

- Replacement

Motor-Fan unit

- Control

- Measurements

- Mechanical cleaning

Electrical cabinet and PLC

Control

Measurements

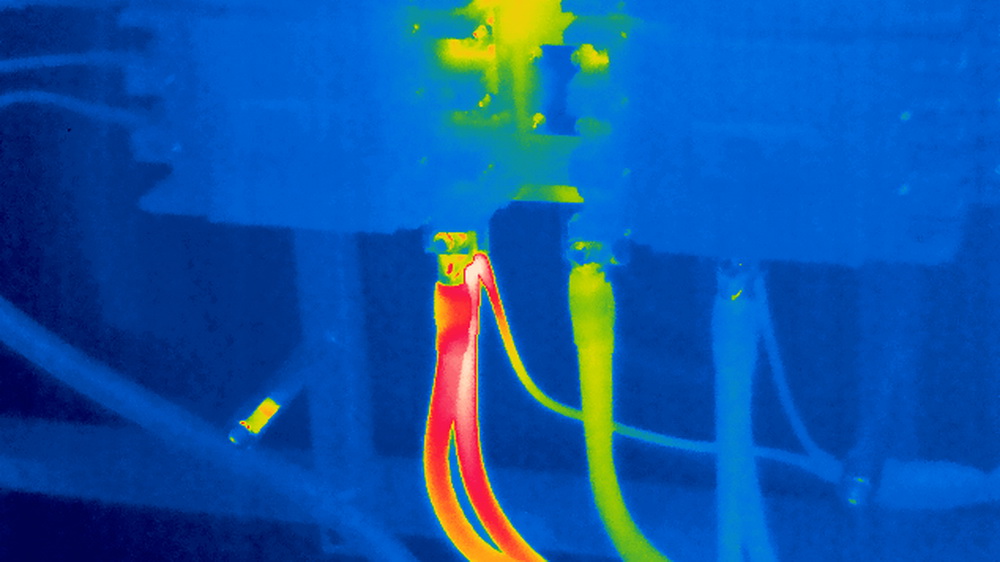

Thermography