- Commitment

- EXPERT

- KNOW-HOW

- Support

Our products

Welcome at JACIR

For over 60 years, JACIR has combined the know-how acquired in aeraulics, thermal and manufacturing materials, in order to offer you an extremely diversified range of products, adapted to all of your needs

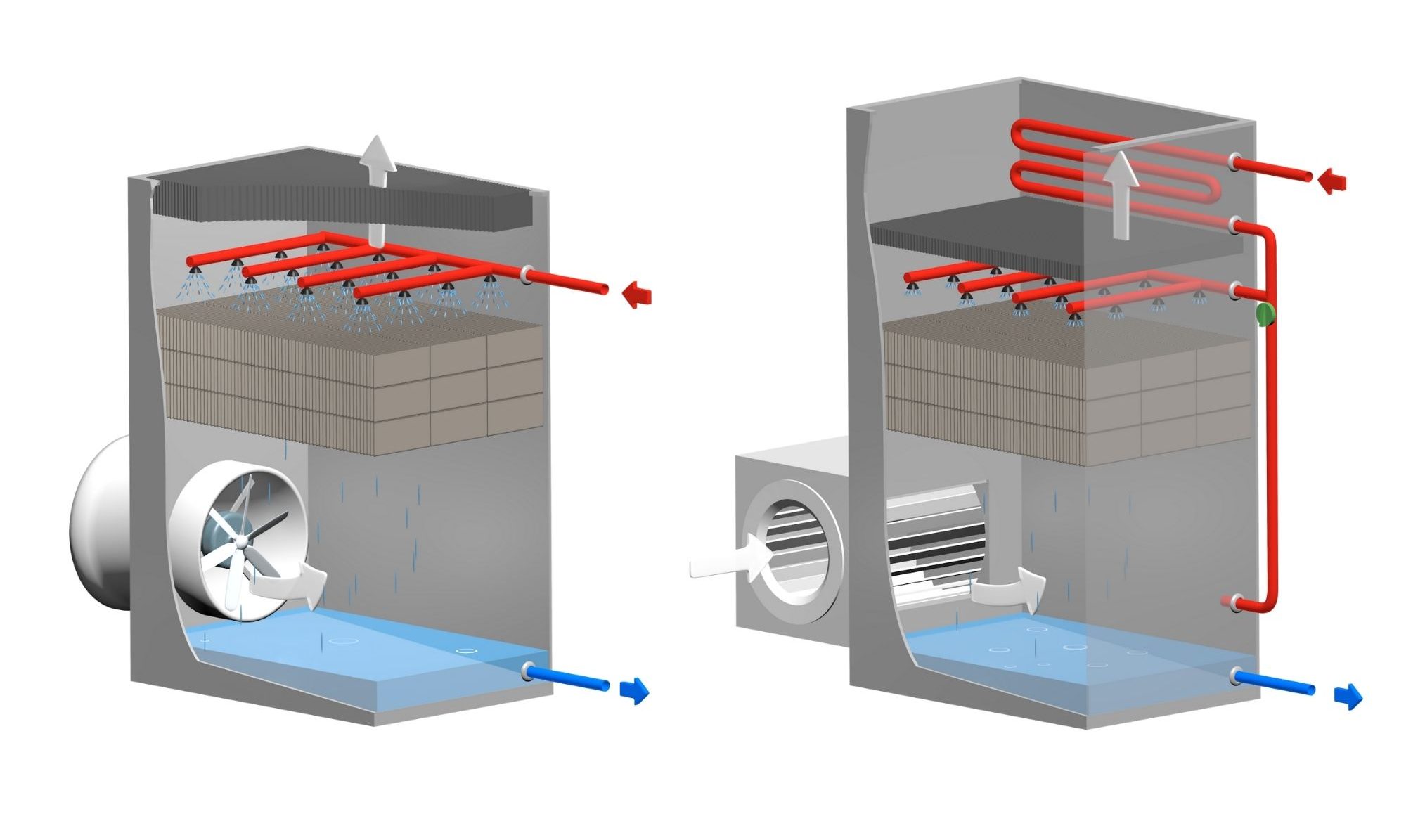

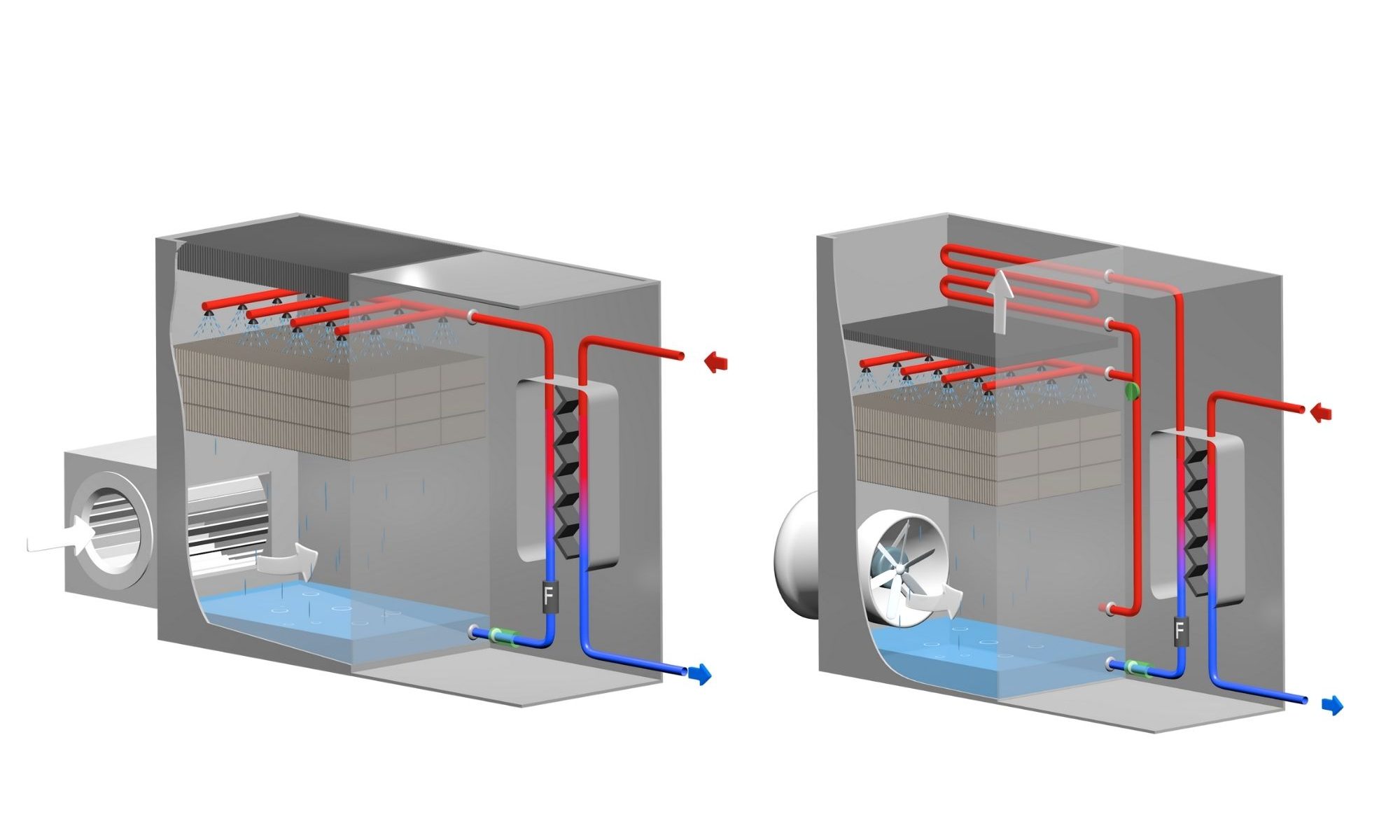

Cooling towerOpen

Open circuit cooling towers are perfectly adapted to clean waters, as well as heavy waters.

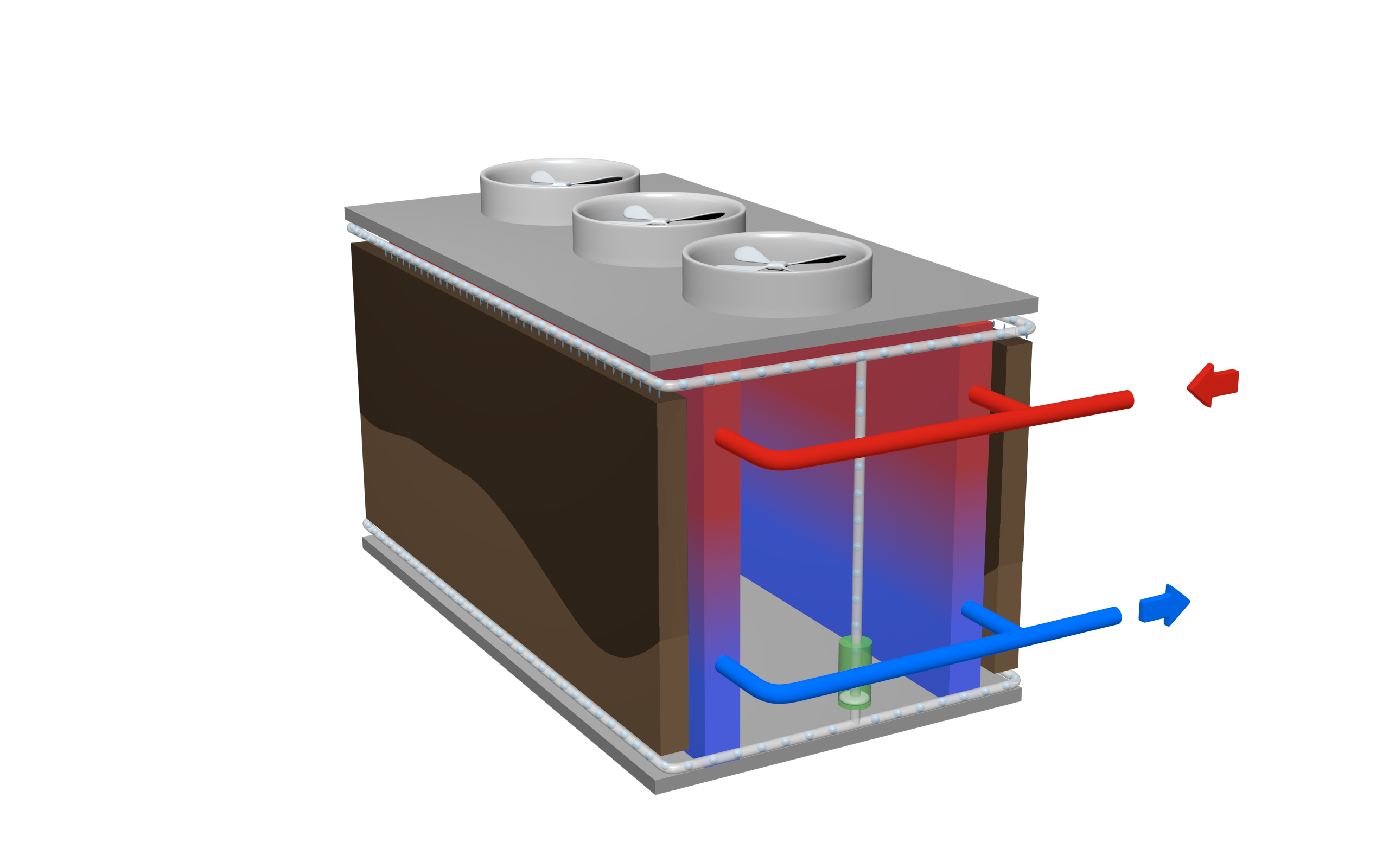

Cooling towerClosed

Closed circuit cooling towers are equipped by centrifugal or axial fans with speed variator.

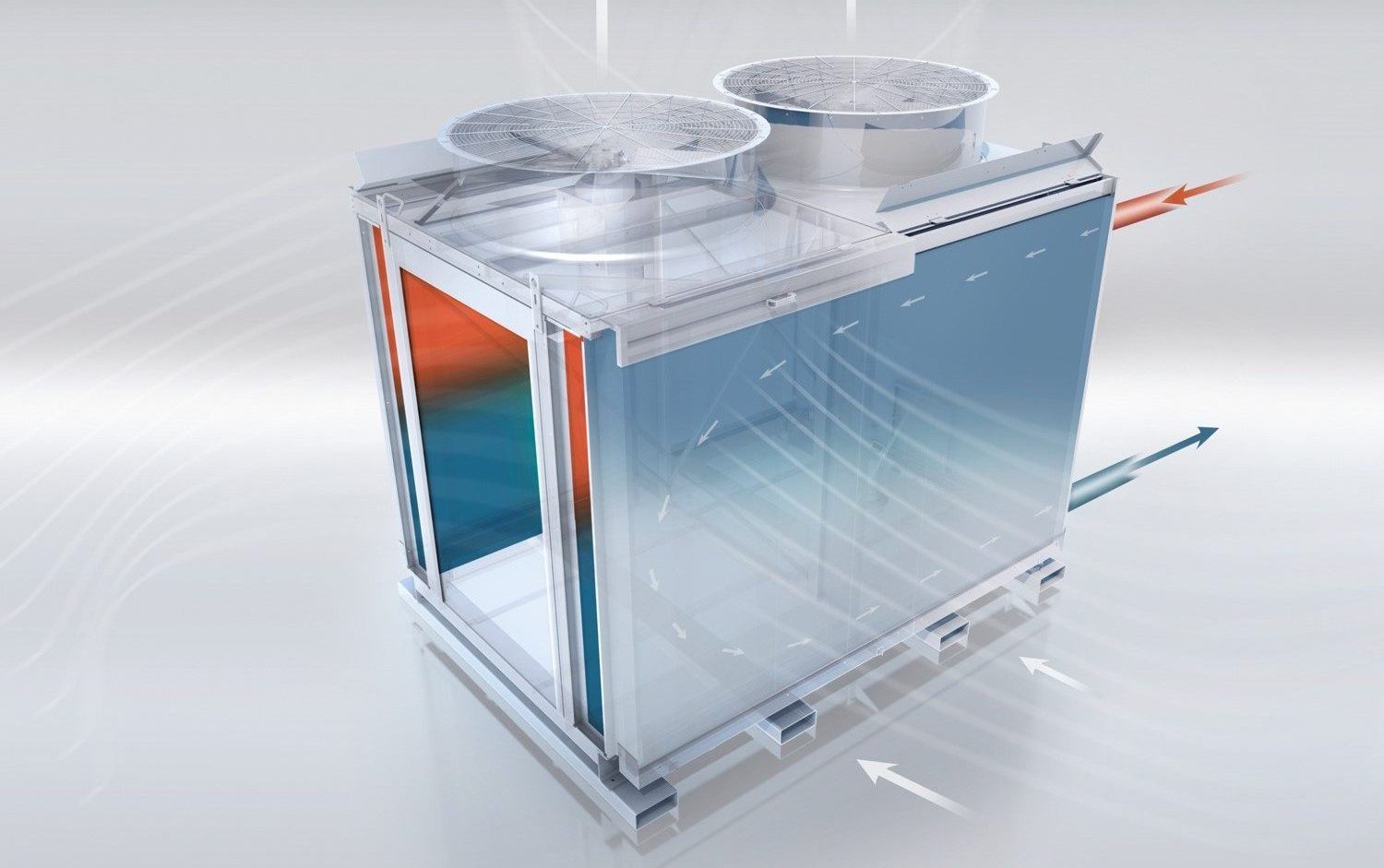

Adiabatic solutionsCooler

TOPAZ NEO adiabatic cooler : intelligent accessibility and secured performance.

Adiabatic solutionsCondenser

Securing the cold chain and overall performance of the refrigeration installation.

French cooling tower manufacturer for 60 years, JACIR supports you by providing you with a team of technicians fully dedicated to the renovation and evolution of your equipment: we are committed .to offering you the best solutions in order to optimize the reliability of your equipments and optimize its performance, in compliance with the requirements No. 2921